Industrial Control Automation Engineering

Providing Project Management and Professional Industrial Automation Control Engineering Servies

Industrial Automation Control Services Provided.

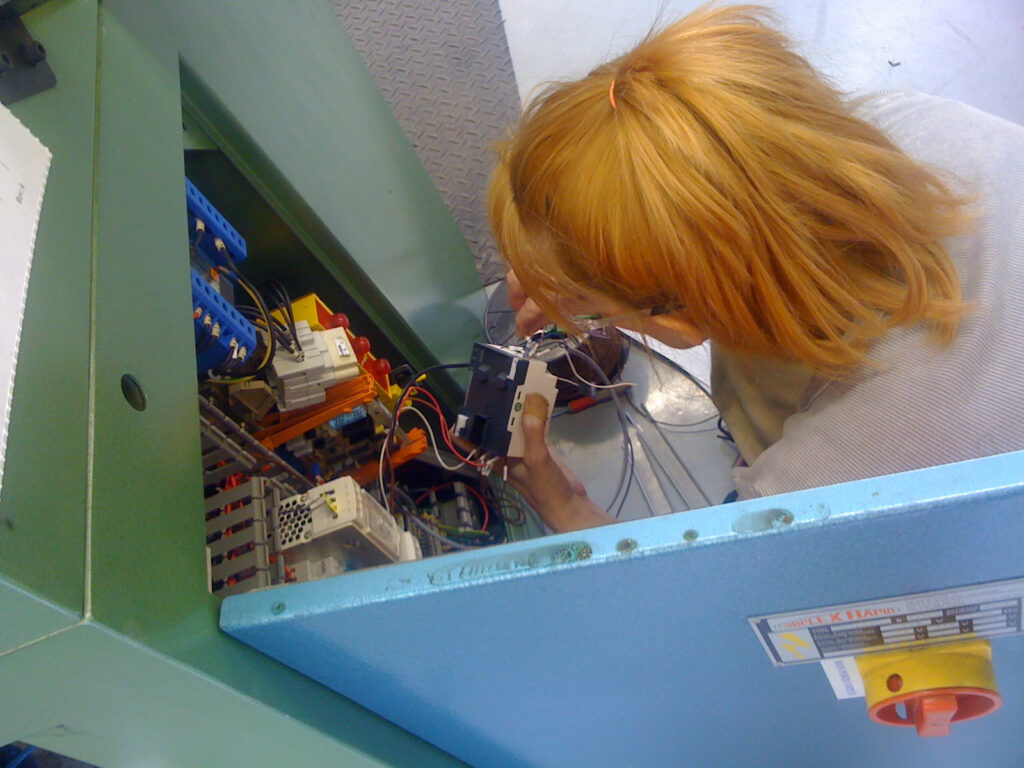

Robot Cell Conveyor Control System

At the customer’s request, the control panel above features Automation Direct DL205 Series PLC.

Automation System Design:

ASR-Engineering Inc will design custom automation systems tailored to your needs. This process could involve conceptualizing the control architecture, specifying hardware and software components, and creating system schematics.

PLC and HMI Programming:

In addition, we will develop control logic using Programmable Logic Controllers (PLCs) to automate industrial processes. Furthermore, we will create Human-Machine Interfaces (HMIs) that allow operators to interact seamlessly with the automation systems.

Robotics Integration:

ASR-Engineering Inc specializes in the integration of robotic systems into industrial processes, enabling them to perform tasks such as material handling, welding, assembly, and more.

SCADA Implementation:

Primarily focused on Ignition (by Inductive Automation), we can deploy Supervisory Control and Data Acquisition (SCADA) systems to monitor and manage industrial processes from a centralized location. Through SCADA, real-time data visualization, trending, and control capabilities are provided.

Industrial Networking:

Based on the architecture of the industrial control system, we will set up communication networks connecting various automation components. This will enable seamless data exchange and coordination between devices, incorporating technologies such as Ethernet IP, Modbus, CAN bus, or many others.

Electrical and Control Panel Design:

For automation projects, ASR-Engineering Inc. offers professional electrical industrial control engineering design services, creating comprehensive control panels and power distribution systems.

Offered as a part of equipment design:

- Power Distribution Circuit Coordination Analysis

- Arc flash Analysis and equipment rating

Process Optimization and Consulting:

When requesting ASR-Enginneersing’s services, we will meticulously analyze existing processes, identify bottlenecks, and propose automation solutions to optimize efficiency, reduce costs, and improve overall productivity.

Safety Systems Integration:

As a critical part of the system design, we will engineer and implement safety protocols and systems to ensure the safe operation of your automated processes, fully complying with recognized industry standards.

Training and Support:

ASR Engineering offers comprehensive training to our client’s staff on operating and maintaining automation systems. Additionally, ongoing technical support and maintenance services can be purchased through an annual contract.

Training:

- As-built equipment Operator and Maintenance

- ARC Flash Hazard Awareness

- PLC Programming, BASIC and ADVANCED

Turnkey Solutions:

Depending on the project, you may request ASR-Engineering to provide a turnkey solution. This means we handle the entire automation project, starting from the conception and design stage, through implementation and Site Acceptance Testing (SAT), and providing ongoing support.

Engineering and Project Management

ASR-Engineering Inc. employs a comprehensive approach to provide the services listed above, leveraging the powerful project management tool Microsoft Project. Here’s how they utilize Microsoft Project to enhance their engineering project management services:

Project Planning:

Firstly, ASR-Engineering collaborates closely with the client to understand the project’s goals and requirements. Subsequently, they create a detailed project plan, including scope definition, objectives, and a comprehensive schedule with milestones, all meticulously organized and visualized using Microsoft Project.

Risk Management:

With Microsoft Project, ASR-Engineering conducts thorough risk assessments, identifying potential risks and developing strategies to mitigate them. They effectively manage risk with the aid of Microsoft Project’s tracking and reporting capabilities.

Resource Management:

ASR-Engineering efficiently allocates and utilizes resources, including their own engineering team, materials, equipment, and budget, all efficiently coordinated through Microsoft Project’s resource management features.

Project Execution:

With Microsoft Project as their project execution backbone, ASR-Engineering effectively oversees the project’s implementation, ensuring seamless coordination, and timely completion of tasks as per the plan.

Quality Control:

ASR-Engineering implements robust quality control measures, tracking and managing quality assurance processes using Microsoft Project to ensure the project outputs meet the required standards and specifications.

Cost Management:

With Microsoft Project’s budgeting and expense tracking capabilities, ASR-Engineering closely monitors project costs, prepares budgets, and efficiently manages expenses to prevent budget overruns and maintain financial viability.

Communication and Collaboration:

ASR-Engineering establishes effective communication channels, seamlessly collaborating with team members, stakeholders, and clients, using Microsoft Project to share real-time project updates and progress reports, promoting transparency and alignment.

Change Management:

ASR – Engineering efficiently handles changes that occur during the project using formal change control processes facilitated by Microsoft Project, managing scope changes and their impact on the project effectively.

Project Monitoring and Reporting:

ASR – Engineering regularly monitors project progress, tracks key performance indicators (KPIs), and generates detailed status reports, leveraging Microsoft Project’s reporting and visualization capabilities to keep stakeholders informed about the project’s health.

Project Closure:

ASR – Engineering ensures all project objectives are met and deliverables are accepted by the client, concluding the project seamlessly and capturing valuable lessons learned, all documented and organized using Microsoft Project.

Industrial Automation Control Panels

Client Engagement and Needs Assessment:

To initiate our process, at ASR – Engineering, we commence by establishing close engagement with our clients, thereby gaining a comprehensive understanding of their unique needs and specific requirements. Through this initial step, we are able to thoroughly assess the project scope and gather detailed information regarding the intended application, environmental conditions, and critical safety considerations.

Meticulous Control Panel Design:

With a comprehensive insight in hand, our team of skilled engineers then proceeds to meticulously craft the control panel layout. By thoughtfully selecting the most suitable components, including PLCs, HMIs, sensors, actuators, and other necessary elements, we ensure a cohesive and efficient design.

Advanced Schematics and Wiring Diagrams:

Subsequently, leveraging cutting-edge design software and advanced technologies, we move forward to create detailed schematics and wiring diagrams. This crucial step ensures that each element functions optimally and adheres to industry standards. Our proficiency further extends to meticulously coordinating power distribution, signal routing, and implementing crucial safety interlocks within the panel structure.

Quality Assurance and Rigorous Testing:

At ASR – Engineering, our unwavering commitment to quality assurance becomes evident. Prior to the assembly phase, we subject every individual component and connection to rigorous testing. Following this, our control panels undergo comprehensive inspections and functional tests to guarantee flawless performance. Emphasizing safety as a top priority, we integrate fail-safe mechanisms and protective features, thereby ensuring that the control panels are not only efficient but also secure within demanding industrial environments.

Transparent Communication and Collaboration:

Throughout every stage of the process, transparent communication and collaboration with our clients remain central to our approach. We provide regular updates, actively seek feedback, and make any necessary adjustments to ensure the final control panel aligns seamlessly with the client’s precise needs.

Precision, Innovation, and Client Satisfaction:

From the initial concept to the ultimate completion, ASR – Engineering’s approach to engineering industrial control panels is characterized by precision, innovation, and an unwavering commitment to client satisfaction.

Field Service Engineering

Comprehensive Field Service Solutions

ASR – Engineering’s field service division offers a comprehensive and hands-on approach to ensuring the optimal functionality and performance of industrial automation systems.

Expert On-Site Support and Maintenance:

Leveraging a team of highly skilled and experienced technicians, ASR – Engineers deliver on-site support, maintenance, troubleshooting, and repair services for a diverse range of automation equipment and processes.

Versatility Across Automation Technologies:

From PLCs and HMIs to robotic systems and SCADA setups, our field service experts are adept at swiftly and effectively addressing technical challenges.

Continuous Excellence Beyond Implementation:

ASR – Engineering’s commitment to excellence extends beyond initial implementation, as our field service division is dedicated to minimizing downtime, maximizing operational efficiency, and upholding the highest standards of reliability.

Responsive Client-Centric Approach:

With a responsive and client-centric approach, ASR – Engineering guarantees a seamless and uninterrupted automation experience, fortified by our unwavering expertise and unwavering commitment to providing top-tier field services.