PROJECT DETAILS

- Date 01 May 2025

- Category Turnkey Engineering Projects

Our projects across industries

In this advanced 22 Million Dollar Web Process for the Water Industry, 121 Coordinated Servo Drives are strategically deployed for precise and synchronized control.

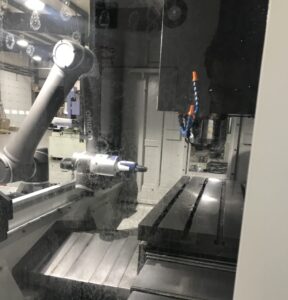

The Omron TM Series Robot expertly tends a Vertical Machine Center (VMC), exhibiting seamless machine automation and precision in this industrial operation.

Powder Pressing with Servos

With a total force of ten tons, this powder pressing system operates on a two-axis setup, incorporating a Compact Logix PLC and Kinetix 6500 Servo drives. Additionally, a third axis is employed to deliver powder media precisely to the mold, ensuring accurate and efficient processing.

Fuel Cell Testing

Designed and constructed exclusively for the Commercial Power Industry, this $1.5M Fuel Cell Test Stand incorporates National Instruments LabView Automation valued at 250K$, showcasing cutting-edge engineering and automation technology.

Hydraulic System Control with Servo Valves

The 100mS Hydraulic Pressure Pulse Test Stand, specifically designed for the Automotive Industry, incorporates a Schneider Electric PLC, to ensure precise and efficient control during testing processes.

Tailored Ultraviolet Process Automation crafted specifically for the stringent demands of the Military and Aerospace Industry, exemplifying exceptional precision and reliability.

Robotic Assembly

Food Industry Automation

Simple Process Control Built for a Manufacture, Who Works in the Food Industry

An automotive-industry-specific All-Pneumatic Motion Assembly Machine engineered with advanced pneumatic control technology to optimize motion control and assembly processes.

This Chemical Plating Process showcases a Pick & Place Gantry Robot, exemplifying advanced automation technology integrated for efficient and precise plating operations.

Food Industry Robotics

Designed exclusively for the Food Industry, this system boasts a Six-Axis Kuka Robot seamlessly integrated with an Allen Bradley Programmable Logic Controller and incorporates an Exor J Smart Touch Screen for advanced automation and efficient operations

Custom-engineered and meticulously crafted for the Water Industry products, this machine showcases an Allen Bradley Compact Logix Programmable Logic Controller, RS Panel View HMI, and Five Power Flex Variable Frequency Drives (VFD), demonstrating superior automation capabilities and precise control.